We kick things off looking at the Micro Go Project from Micro.

This month, we speak to Godfrey at Micro.

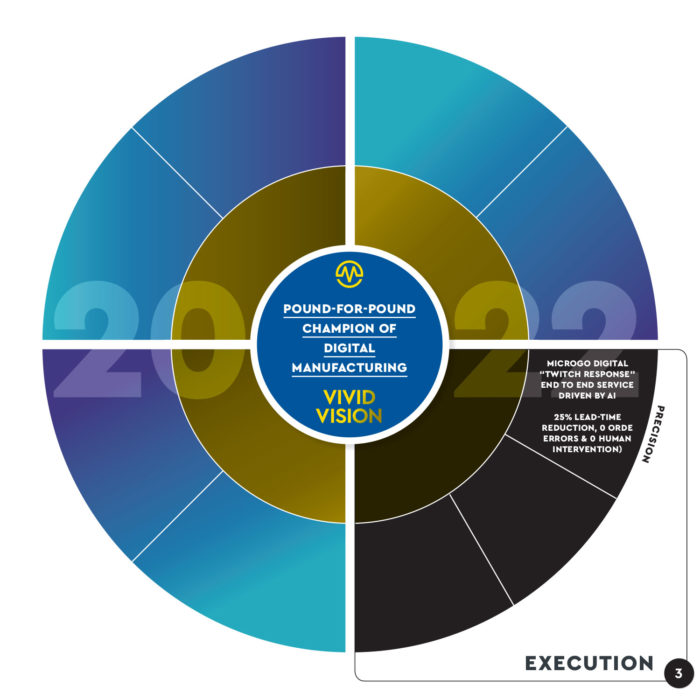

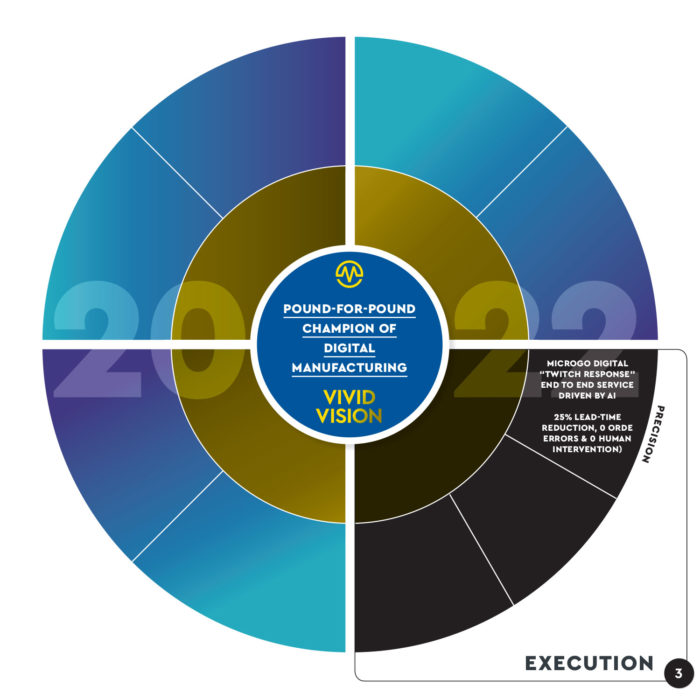

1. What are you currently working on related to our Vivid Vision strategy?

I am responsible for the MicroGo project.

MicroGo is is an initiative that involves upgrading all our front-and-back-end operations so that our internal systems are connected with our external systems. In doing so, we will streamline the flow of information in and out of the business with minimal human intervention and allow real-time data to increase the speed in which we operate and attend to customer needs.

Our objective is that in 3 years, Micro will have integrated all systems that generate data with one another and apply data analytical tools to build scenarios, anticipate events, and build value in everything we do. In Michael (Tucci’s) words, “we will become a technology company that happens to manufacture components”.

2. What’s an example?

For example, by using B2B connections we will integrate our systems to the systems of our major customers, and start gathering data directly from their MRPs into our planning tools. While it might not be an entirely new idea, the difference with MicroGo is that in our business, Micro is responsible for planning and delivering parts in a way that keeps inventory down and avoids excess production. We will improve the way we do this by building systems that will detect possible issues before they happen and quickly take decisions to reduce unnecessary costs.

Another example is that by using IoT in our production plant, we connect our machines to our Planning, Production, Quality, and Maintenance systems. This means that we will now use the same data to coordinate tasks and avoid unexpected situations. This will eliminate silos in our operations, create greater transparency and build trust in the data. We believe it’ll allow us to eliminate multiple control points and “just in case” procedures.

The next step is that by integrating our machines and quality systems to the ERP (IoT), we can build a single flow of information that will push demand into our production lines. This production gets audited by quality systems digitally (and with a high level of accuracy), and we collect information that gets pushed back into the ERP for proper control and analysis that will help improve the following production runs. Additional data gets collected along the process and will then be available for our engineering teams and our customers, helping us determine recommendations on new product design and process design that will reduce costs internally and externally to our customers.

3. What are you trying to achieve right now?

The specific objectives for 2019 are:

- Automating customer purchase orders and ERP entry

- Integration of ERP and production machines using IoT solutions that convert machines into data generators / trackers

- Applying RPA and automation to accounting, planning, purchasing, and logistics tasks in order to reduce bookkeeping and “control” tasks

4. What are your findings, breakthroughs, challenges so far?

Collaboration:It’s a significantly sized task and will definitely require all hands on deck and every department in the company working to make things happen quickly. Everyone at Micro is aware that the Vivid Vision is our true north and encapsulates where we are headed for the next two and a half years. This is now even part of our day to day decision-making because before we make decisions to solve something, we are already asking if what we will apply or invest time into is aligned with this vision of Micro.

Solution fit: Finding the right solutions that align closely to what we envision has also been a challenge.

On the positive side, we have launched our first solution after 6 months, and it is working very well. This has built confidence with the team and the project is getting more and more support from all departments who are now asking to digitize and automate tasks that will free up their time.

5. What value do you expect this will offer our customers in the future?

The value of this project for our customers is infinite at this point.

MicroGo will show customers that we are technologically advanced and that we are capable of adapting our systems to theirs in order to streamline processes and react in minutes to their needs (not days). We will also have the ability to anticipate errors or false signals that their planning teams may be omitting, and help them resolve issues before they happen, putting Micro in a groundbreaking position, not just as a critical supplier, but as forecaster and consultants, offering solutions before they know that they need them.

MicroGo gives us the opportunity to produce components at a level no other manufacturing company is currently capable of doing it, especially when you consider that we will be a 6 sigma company.