Forecasting the future of the 3D printing market has always been a tricky task to tackle. Being a relatively new technology, many analysts simply did not understand exactly what the future applications of this magical new type of machine would entail.

First appeared in Type A Machines on May 8, 2017 – Article Link.

When the buzz about 3D printing started to peak in the late 2000’s and early 2010’s, the phrase “a 3D printer in every home” was thrown around like candy. Soon, it was realized that this would not be the case, 3D printing simply just isn’t for everybody. The process isn’t as easy as just pressing a button and voila, you’ve got an object. 3D printing involves 3D design, post-processing, and general knowledge of the machinery for it to work to its full capability. This led to some overly optimistic forecasts of the 3D printing industry which have failed to become a reality.

Early on, Type A Machines saw that “a 3D printer in every home” was not where the industry was headed. Instead, we saw the growth of the industry coming from a different place, manufacturing. The Series 1 Pro was designed with this use-case in mind. The fully accessible and open build design, the easily replaceable parts, and the low total cost of ownership were all features made to serve the needs of the manufacturing professional. In addition, we developed the industry’s first parallel production FDM 3D printing solution, the Print Pod. Industry analysts have agreed that this is the future of 3D printing, and it has been reflected in recent forecasts.

Industry analysts across the board are predicting meteoric rises in total sales of printers, revenue, and potential applications by 2020. The rise of 3D printing as a solution for manufacturing companies will play a huge role in this projected growth.

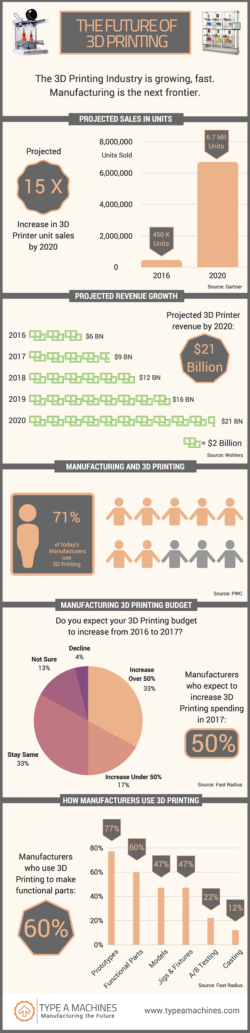

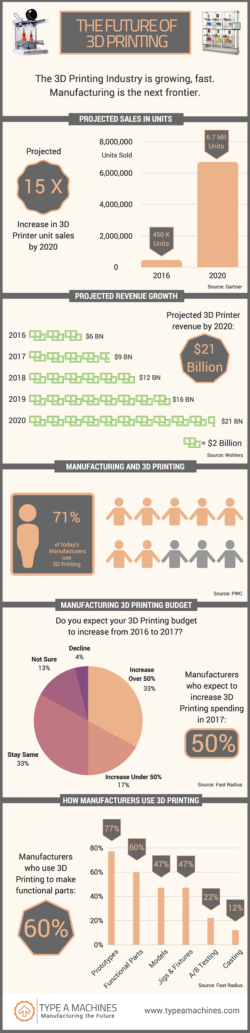

This infographic shows just how much the 3D printing industry is expected to grow in the next 5 years:

15 Times More 3D Printing Units Expected to be Sold by 2020

In their report, “Forecast: 3D printers, Worldwide 2016”, Gartner saw 3D printer unit sales jump 108% from 2015 to 2016 (219,168 units shipped in 2015 and 455,772 units in 2016). They do not see that growth slowing down anytime soon either. Gartner has projected that in 2020, more than 6.7 million 3D printing units will be shipped. That is a 15-fold rise from the 2016 totals.

$21 Billion Projected 3D Printing Revenue in 2020

Gartner is not alone in their bullish predictions of the 3D printing market. Wohlers has projected that the worldwide 3D Printing revenue was $6 billion in 2016, and will continue to grow to $9 billion in 2017, $12 billion in 2018, $16 billion in 2019, and a whopping $21 billion in 2020.

71% of Manufacturers are Currently Using 3D Printing

We’ve seen the projections of how the 3D printing Industry will rise as a whole. Now we will explore the role manufacturers will play in this growth. In a survey conducted with manufacturers, PWC found that 71% use 3D printing in some capacity (up from 66% the previous year). This survey also found that 20% of manufacturers are using 3D printing to produce final parts, up from 10% the previous year.

50% of Manufacturers Expect to Increase 3D Printing Spending in the Next 12 Months

As we saw from the PWC survey, manufacturers are already adopting 3D printing. According to a survey by Fast Radius, not only have manufacturers adopted 3D printing, but they are having good enough results that they are planning to increase spending in the next 12 months. Over 50% of the surveyed manufacturers plan to make that increase in spending, and 33% say they plan to increase spending by over 50% from the year before.

60% of Manufacturers use 3D Printing to Make Functional Parts

Manufacturers who use 3D printing will use it for many different purposes. From simply experimenting to prototyping to printing functional parts. According to the same Fast Radius survey, the main use of manufacturers have with 3D printing remains for prototyping (77%), but catching up to that number is printing of functional parts (60%).

Across the board, analysts see the potential growth of the 3D printing industry. From units sold, to total revenue, the growth will be astronomical over the next four years. One of the main drivers of this growth will be from the manufacturing industry who are quickly adopting 3D printing as a viable alternative to traditional manufacturing methods. Going beyond prototyping and on to final part production will see 3D printing become a major player in the manufacturing industry. Type A Machines will continue to support this growth with products made with the manufacturer in mind from the Series 1 Pro to the Print Pod.